REDISIGN AND MANUFACTURE LARGE METAL COMPONENTS BY DIGITAL MANUFACTURING

(IN852A 2018/87)

The main objective of the AM0DIÑO project is the development and implementation of a methodology of (re) design and manufacturing aimed at digital and efficient manufacturing with zero defects of large components and high added value in steel and bronze for the equipment and shipbuilding sector. The concept of efficient and digital manufacturing will focus on Additive Manufacturing by Direct Energy Deposition (FADDE). Specifically, the project will address two technologies, mainly: Laser Metallic Powder Deposition (LMD) and Electric Arc Additive Manufacturing (WAAM), as they are methodologies that provide great processing flexibility, high metal deposition rates and the use of known facilities for the metalworking sector.

The project arises from the need of many companies to manufacture or repair medium-large components for different sectors such as the equipment, machine tool, naval or wind power industry. Using conventional technologies, they face the competition of developing countries, which is difficult to combat in terms of price and delivery time due to the looser legislation in environmental terms and cheaper labor. The only way to be competitive is to change to productive processes that consume less resources and time, obtaining at the same time a product of added value with greater profit margin. Increasing the competitiveness of the Galician industrial sector goes irremediably through its “reinvention”, through the “search for new forms of production that boost competitiveness”.

In this sense, one of the technologies that is contributing the most to the reinvention of productive processes in recent years is Additive Manufacturing (FA), which has become a key enabling technology towards the industry of the future. Although the dust bed FA is the variant that has experienced a major advance in recent years, the FADDE technologies present a great potential for application in the metal-mechanic industry. Its main advantage lies in its higher associated deposition rate and, therefore, its scalability to large components, multiplying the possibilities as far as the design is concerned, which allows to manufacture optimized components from a material saving point of view and of structural behavior, giving them a significantly greater added value.

CONSORCIO AMODIÑO

To meet this ambitious challenge, a multisectoral consortium of five Galician SMEs has been consolidated, with the skills and knowledge necessary to cover all project activities:

EASYWORKS will be the project coordinator and its main role will be the redesign and planning of the process for FA through the specific development of CAx technologies.

UNIMATE, as a turnkey industrial cell installer, will extrapolate its knowledge for the development in THUNE EUREKA of the FADDE cell.

THUNE EUREKA will develop in collaboration with UNIMATE the FADDE cell in its facilities for the manufacture of large tools for internal use.

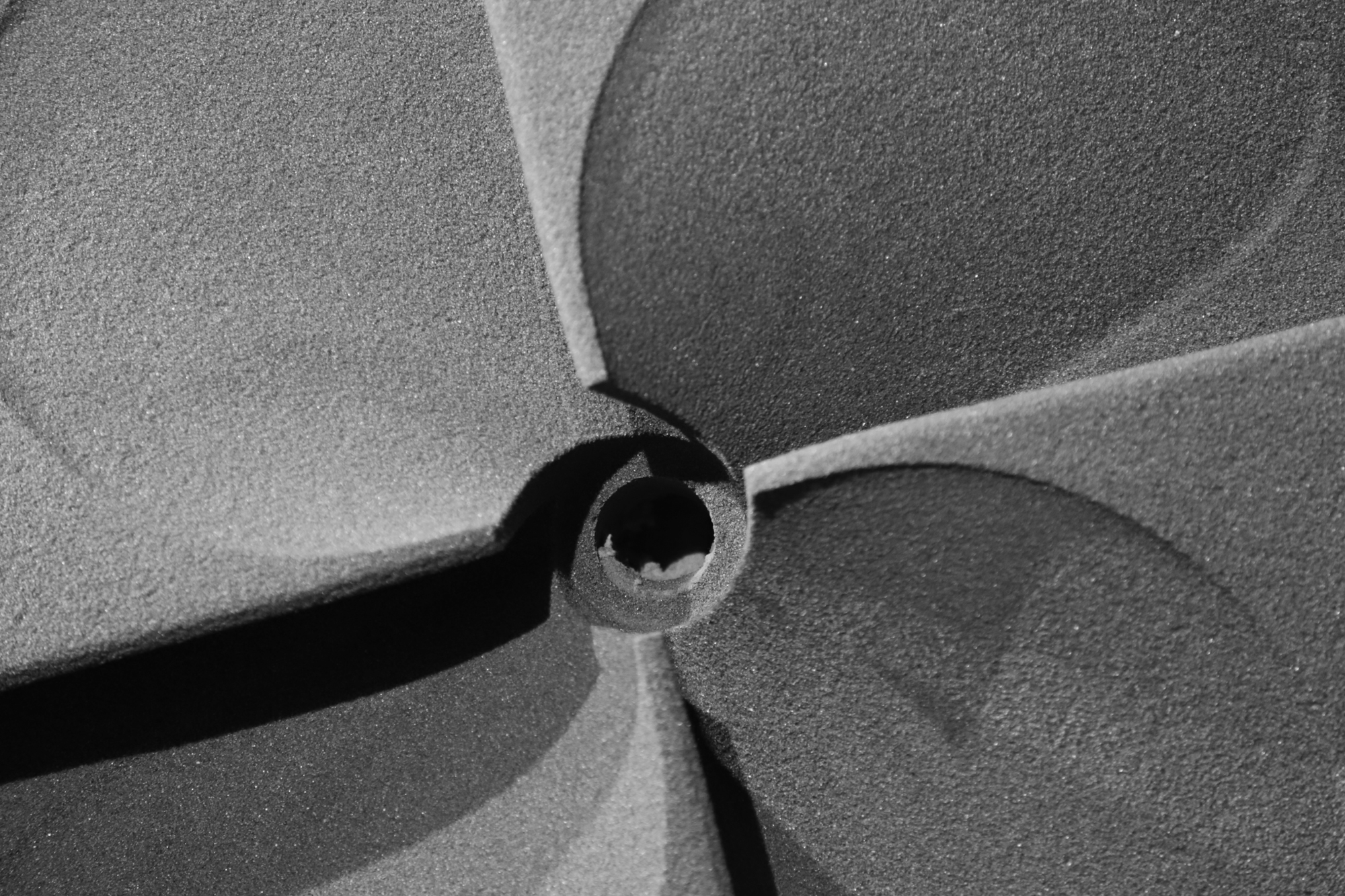

FUNDICIONES ADRIO will develop new designs of propellers supported by the wide design possibilities offered by the FA and that will be achieved with the manufacture of a vane by topologically optimized WAAM.

MAXIMINO SEOANE will manufacture a gas extractor wheel by FA, replacing several manufacturing operations with one. In addition, through the acquisition of design and manufacturing knowledge for FADDE, it will be able to offer its clients design and engineering services, in order to lower the manufacturing costs of the products it manufactures for its customers.

With the aim of promoting innovative activity within companies, strengthen their international leadership capacity and improve their competitive position, the consortium will count on the support of technological center AIMEN, with extensive experience in the development of new advanced manufacturing processes, and particularly in those related to Additive Manufacturing.

FUNDING AMODIÑO

The AM0Diño project, framed in the CONECTAPEME 2018 program, is funded by the Xunta de Galicia through the Galician Innovation Axencia (GAIN) and the support of the Ministry of Economy, Emprego and Industry and is co-financed by FEDER Funds in the framework of axis 1 of the Feder Galicia 2014-2020 operational program.